Sealed Air Inflatable Void Fill

What is Sealed Air Inflatable Void Fill?

Sealed Air Inflatable Void Fill is a cutting-edge packaging solution designed to protect your products during shipping. These inflatable cushions act as a protective barrier, filling empty spaces within packages to prevent damage and ensure secure delivery.

How does it work?

The void fill cushions are inflated on-site using specialized equipment. Once inflated, they conform to the shape of your products, creating a customized protective layer that absorbs shocks and vibrations during transit.

Is it eco-friendly?

Yes! Sealed Air prioritizes sustainability. The void fill cushions are often made from recyclable materials, minimizing environmental impact. They are a responsible choice for businesses aiming to reduce their carbon footprint.

Can it be used for fragile items?

Absolutely! The inflatable void fill cushions are versatile and can be adjusted to provide optimal protection for fragile or delicate items. Say goodbye to worries about broken or damaged products during shipping.

How cost-effective is this packaging solution?

Sealed Air Inflatable Void Fill offers a cost-effective packaging solution by reducing the need for excess packaging materials. Its efficient design not only saves on shipping costs but also enhances overall operational efficiency.

Upgrade your shipping strategy with Sealed Air Inflatable Void Fill—reliable, eco-friendly, and tailored for the protection of your products in transit!

Electric Air Cushion Machine

What exactly is an Electric Air Cushion Machine?

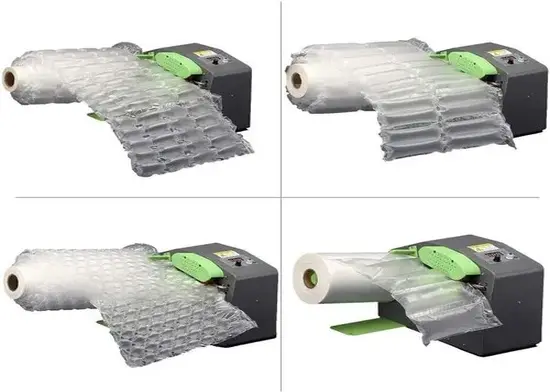

An Electric Air Cushion Machine is a revolutionary packaging device designed to create inflatable cushions on demand. It's a versatile solution for businesses looking to enhance their shipping and packaging processes.

How does the machine operate?

Operating the Electric Air Cushion Machine is a breeze. It inflates specially designed film rolls, producing customized air cushions that provide superior protection for various products during transit.

Is it suitable for all types of packaging needs?

Absolutely! Whether you're shipping delicate electronics or sturdy goods, this machine adapts to diverse packaging requirements, ensuring a secure and tailored solution.

Does it save costs compared to traditional packaging methods?

Without a doubt! By producing air cushions on-site, businesses eliminate the need for pre-filled packaging materials, reducing storage costs and optimizing overall efficiency.

Is maintenance complicated?

Not at all. The Electric Air Cushion Machine is designed for durability and user-friendly maintenance, ensuring smooth and uninterrupted performance.

Upgrade your packaging game with the Electric Air Cushion Machine an efficient, cost-effective, and customizable solution for all your shipping needs.

Fill Air Cushion Machine

What is a Fill Air Cushion Machine?

A Fill Air Cushion Machine is a game-changer in packaging, designed to create inflatable air cushions on demand for superior product protection.

How does the machine operate?

Operating the Fill Air Cushion Machine is simple. It inflates specialized film rolls, creating custom air cushions that conform to the shape of your products, ensuring a secure and tailored packaging solution.

Is it versatile for different packaging needs?

Absolutely! The Fill Air Cushion Machine adapts to a variety of products, making it a perfect choice for businesses with diverse packaging requirements, from fragile items to bulkier goods.

Does it save costs compared to traditional packaging methods?

Yes! By generating cushions on-site, businesses eliminate the need for pre-filled packaging materials, reducing storage costs and optimizing overall efficiency.

How user-friendly is the machine?

Extremely user-friendly. The Fill Air Cushion Machine is designed for easy operation and maintenance, ensuring a hassle-free experience for businesses looking to enhance their packaging processes.

Upgrade your packaging game with the Fill Air Cushion Machine – the efficient, cost-effective, and customizable solution for all your protective packaging needs.

Sealed Air Cushion Machine

What is a Sealed Air Cushion Machine?

A Sealed Air Cushion Machine is a revolutionary packaging tool designed for creating customized inflatable cushions on demand, providing top-notch protection for your products during shipping.How does the machine operate?

Operating the Sealed Air Cushion Machine is a breeze. It inflates specialized film rolls, transforming them into tailored air cushions that adapt to the shape of your products, ensuring a secure packaging solution.

Is it suitable for various packaging needs?

Absolutely! The Sealed Air Cushion Machine is versatile and adaptable, making it an ideal choice for businesses with diverse packaging requirements, whether for fragile items or bulkier goods.

Does it contribute to cost savings?

Yes! By generating cushions on-site, businesses eliminate the need for pre-filled packaging materials, reducing storage costs and optimizing overall efficiency. It's a cost-effective solution for modern packaging needs.

How user-friendly is the machine?

Extremely user-friendly. The Sealed Air Cushion Machine is designed for easy operation and maintenance, ensuring a hassle-free experience for businesses aiming to elevate their packaging processes.

Upgrade your packaging efficiency with the Sealed Air Cushion Machine – a versatile, cost-effective, and user-friendly solution for all your protective packaging needs.

Air Cushion Pillow Films

What are Air Cushion Pillow Films?

Air Cushion Pillow Films are innovative packaging materials designed to provide superior protection for your products during shipping. These films transform into inflatable cushions, acting as a cushioning and void-fill solution.

How do the films work?

Simply load the Air Cushion Pillow Films into a compatible packaging machine, and it will inflate the films, creating customized air pillows. These pillows conform to the shape of your products, ensuring a snug fit and reliable protection.

Are they suitable for various products?

Absolutely! Air Cushion Pillow Films are versatile and adaptable, making them an ideal choice for businesses with diverse packaging needs. They work well for fragile items, electronics, and a wide range of products.

Do they contribute to cost savings?

Yes! Using Air Cushion Pillow Films allows businesses to create cushions on-demand, eliminating the need for pre-filled packaging materials. This not only saves on storage costs but also optimizes overall packaging efficiency.

Are the films eco-friendly?

Many Air Cushion Pillow Films are designed with sustainability in mind, using recyclable materials. Choosing these films reflects a commitment to environmentally responsible packaging practices.

Upgrade your packaging game with Air Cushion Pillow Films – a versatile, cost-effective, and eco-friendly solution for all your protective packaging needs.

Air Cushion Film Roll

What is an Air Cushion Film Roll?

An Air Cushion Film Roll is a key component in modern packaging, designed to be used with cushioning machines. It's a flexible and versatile material that transforms into protective air cushions, ensuring secure packaging for various products.

How does the film roll work with cushioning machines?

The Air Cushion Film Roll is loaded into compatible cushioning machines, which then inflate and shape the film into customized air cushions. These cushions conform to the shape of your products, providing a protective layer during shipping.

Is the film roll suitable for different packaging needs?

Absolutely! The Air Cushion Film Roll is adaptable to a wide range of products, making it an ideal choice for businesses with diverse packaging requirements, from fragile items to bulkier goods.

Does it enhance cost efficiency in packaging?

Yes! Using Air Cushion Film Rolls allows businesses to create cushions on-demand, eliminating the need for pre-filled packaging materials. This not only saves on storage costs but also optimizes overall packaging efficiency.

Is the film roll eco-friendly?

Many Air Cushion Film Rolls are designed with sustainability in mind, using recyclable materials. Choosing these rolls reflects a commitment to environmentally responsible packaging practices.

Elevate your packaging strategy with Air Cushion Film Rolls – a versatile, cost-effective, and eco-friendly solution for all your protective packaging needs.

.webp)

Air Cushion and Void Filler Machine

What is an Air Cushion and Void Filler Machine?

An Air Cushion and Void Filler Machine is a state-of-the-art packaging solution designed to create inflatable cushions and fill voids within packages for optimal product protection during shipping.

How does the machine operate?

Operating the machine is seamless. It inflates specialized film rolls, creating customized air cushions and void fillers that adapt to the shape of your products, ensuring a secure and tailored packaging solution.

Is it versatile for different packaging needs?

Absolutely! The Air Cushion and Void Filler Machine is adaptable to a wide range of products, making it an ideal choice for businesses with diverse packaging requirements, from fragile items to bulkier goods.

Does it contribute to cost savings?

Yes! By generating cushions and void fillers on-site, businesses eliminate the need for pre-filled packaging materials, reducing storage costs and optimizing overall efficiency. It's a cost-effective solution for modern packaging needs.

How user-friendly is the machine?

Extremely user-friendly. The Air Cushion and Void Filler Machine is designed for easy operation and maintenance, ensuring a hassle-free experience for businesses looking to enhance their packaging processes.

Upgrade your packaging efficiency with the Air Cushion and Void Filler Machine – a versatile, cost-effective, and user-friendly solution for all your protective packaging needs.

Air Column Machine

What is an Air Column Machine?

An Air Column Machine is a cutting-edge packaging tool designed to create protective air columns for secure product packaging. It's an innovative solution for businesses seeking efficient and customizable packaging options.

How does the machine work?

Operating the Air Column Machine is straightforward. It inflates specialized film rolls, producing individual air columns that form a protective barrier around your products. This tailored packaging ensures items arrive at their destination intact.

Is it suitable for various packaging needs?

Absolutely! The Air Column Machine adapts to diverse products, making it an ideal choice for businesses with varying packaging requirements. It provides a versatile and secure solution for items of all shapes and sizes.

Does it contribute to cost savings?

Yes! By generating air columns on-site, businesses eliminate the need for excessive packaging materials, reducing storage costs and optimizing overall efficiency. It's a cost-effective and eco-friendly solution for modern packaging challenges.

How user-friendly is the machine?

Extremely user-friendly. The Air Column Machine is designed for easy operation and maintenance, ensuring a hassle-free experience for businesses looking to enhance their packaging processes.

Upgrade your packaging strategy with the Air Column Machine – a versatile, cost-effective, and user-friendly solution for all your protective packaging needs.

Biodegradable Paper Air Cushion Machine

What is a Biodegradable Paper Air Cushion Machine?

A biodegradable paper air cushion machine is an innovative packaging solution designed to create protective air cushions using eco-friendly paper materials. These machines produce versatile packaging elements that act as cushioning or void fillers, safeguarding products during shipping and handling.How does it Work?

The machine takes rolls of special biodegradable paper and transforms them into inflated air cushions. It utilizes a combination of air and paper to create these cushions, which can vary in size and shape, offering adaptable packaging options for different products.

Why Choose Biodegradable Paper Air Cushions?

The shift towards eco-friendly packaging solutions is crucial for reducing environmental impact. Biodegradable paper air cushions offer a sustainable alternative to traditional plastic-based packaging materials. They decompose naturally, minimizing pollution and leaving behind no harmful residues.

What are the Benefits of Using this Machine?

Is it Easy to Operate?

Yes, most biodegradable paper air cushion machines are user-friendly. They often feature simple controls and adjustable settings for creating cushions of different sizes, ensuring ease of use for packaging needs.Where can I Use Biodegradable Paper Air Cushions?

These cushions are suitable for various industries such as e-commerce, electronics, cosmetics, and pharmaceuticals. They offer an adaptable solution for shipping and protecting items of different shapes and sizes.

Are They as Effective as Other Packaging Materials?

Yes, biodegradable paper air cushions are as effective as traditional packaging materials in terms of protection during transportation. They provide excellent shock absorption and cushioning to safeguard products against damage.

In Conclusion

Investing in a biodegradable paper air cushion machine not only ensures secure packaging for your products but also aligns with sustainable business practices. By choosing eco-friendly options, you contribute to a healthier environment while meeting packaging needs effectively.

Air pad packaging machine

What is an air pad packaging machine, and how does it work?

An air pad packaging machine is a device used to create protective air cushions for packaging and shipping. These machines typically use rolls of film, which are inflated and sealed on-demand to create air-filled cushions that safeguard items during transit.

What are the benefits of using air pad packaging?

Air pad packaging offers superior protection, cushioning fragile items against shocks and impacts during shipping. It's lightweight, versatile, and reduces material waste compared to traditional packaging materials like foam or bubble wrap.

Can air pad packaging machines accommodate different packaging needs?

Yes, air pad packaging machines come in various models and sizes, catering to different packaging volumes and requirements. Some machines offer adjustable settings for cushion size, air pressure, and speed to suit diverse packaging needs.

Are air pad packaging materials environmentally friendly?

Many air pad films are recyclable and made from materials like LDPE (low-density polyethylene), which can be recycled through appropriate channels. Choosing eco-friendly films contributes to sustainable packaging practices.

How durable are air pad cushions?

Air pad cushions are resilient and provide excellent protection against impacts. The film's design and the machine's ability to create strong seals ensure durability throughout the shipping process.

Can air pad packaging machines integrate with existing packaging lines?

Yes, most air pad packaging machines are designed for easy integration into existing packaging setups. They can be adapted to work seamlessly with conveyor systems or other packaging machinery.

What industries benefit most from using air pad packaging machines?

Industries involved in e-commerce, electronics, pharmaceuticals, and logistics benefit greatly from air pad packaging. These machines streamline the packaging process and ensure secure shipping for a wide range of products.

How cost-effective are air pad packaging machines?

While initial investment costs exist, the efficiency, reduced material usage, and minimized shipping damages often result in cost savings in the long run. Calculating the overall savings in materials and reduced product damages helps determine cost-effectiveness.

Conclusion:

Air pad packaging machines offer a versatile and efficient solution for protecting goods during shipping. With customizable features, eco-friendly options, and compatibility with various industries, these machines provide a cost-effective and reliable packaging solution. For specific packaging needs, selecting the right machine and film type is essential for optimal results. For more information tailored to your requirements, consult packaging experts or suppliers.